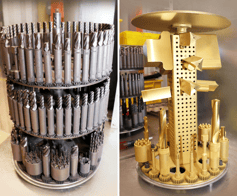

PVD QUAD Coating Improves Tool Life in Iron-Based Machining - Outstanding Results

Outstanding results are happening when machining iron-based materials. Special tools designed and manufactured by TE as well as tools reground at TE have proven results. Our TIXCO3 PVD coating is a key driver of success and a real winner when machining cast iron, nodular iron, and compacted graphitic iron (CGI). Tool life results are exceeding expectations. The TE Tech Team is being asked to look at additional process applications. Here are a few examples.

Outstanding results are happening when machining iron-based materials. Special tools designed and manufactured by TE as well as tools reground at TE have proven results. Our TIXCO3 PVD coating is a key driver of success and a real winner when machining cast iron, nodular iron, and compacted graphitic iron (CGI). Tool life results are exceeding expectations. The TE Tech Team is being asked to look at additional process applications. Here are a few examples.

American Automotive Manufacturer – CGI Casting

- Tool Type

- Carbide coolant fed step drill, helical flute

- Baseline

- Customer regrinds in-house and has tool coated with competitors TIALN

- TE Solution

- Regrind + Recoat at Tru-Edge – use TIXCO3 coating

- Results

- Doubled tool life from 2,000 to 3,000 parts to 4,000 to 6,000 parts

- Tru-Edge Value

- $58.80 per tool to regrind and recoat

- Consistent performance of tools; reduction in downtime

- TE Tech Team invited to look at additional applications for improvements

American Truck Engine Manufacturer - CGI Casting

- Tool Type

- Carbide coolant fed step drill, helical flute

- Baseline

- Competitor regrinds tool and has tool coated with ALTIN

- TE Solution

- Regrind + Recoat at Tru-Edge – use TIXCO3 coating

- Results

- Increased tool life 3X with consistent tool life resulting in higher throughput

- Tru-Edge Value

- $42.70 per tool to regrind and recoat

- Consistent tool life; reduced unexpected tool breakage

- Customer uses the TE Pick-Up & Delivery Service

Asian Tier 1 Automotive Parts Manufacturer - Nodular Iron Casting

- Tool Type

- Carbide coolant fed drill + counterbore + chamfer tool, G-drill (straight flute)

- Baseline

- Tru-Edge design and manufacture tool, uncoated per customer request

- TE Improvement

- Add TIXCO3 coating

- Results

- Original tool – 2,500 to 3,500 parts

- TIXCO3 tool – 5,000 to 6,500 parts

- Tru-Edge Value

- $14.24 – cost to add TIXO3 coating to tool

- Customer uses the TE Pick-up & Delivery Service

- Customer works with TE engineer team for concurrent engineering programs

If you want to learn more on how you can improve the life of your cutting tools when machining iron-based materials give us a call at 419-678-4991 or visit our website at www.tru-edge.com. We’ll get our TE Tech Team involved and simplify your iron-based machining processes!

.jpg)