How to Select the Right Rotating Tool for Your Application

There are key design elements to consider when selecting a multi-function drill. Old generation, step twist drills have been around for years and remain a go-to design. For high production machining, the straight flute G-drill design has gained popularity and offers advantages over a step drill. Recent interest in helical flute, subland drill designs has reemerged and a viable option to extend tool life and allow for more regrinds.

Let’s take a moment to review each tool type noting that tools can be manufactured in a variety of cutting materials: high-speed steel (HSS), cobalt high-speed steel (COHSS), and carbide – coolant fed and non-coolant fed – PVD coated and uncoated.

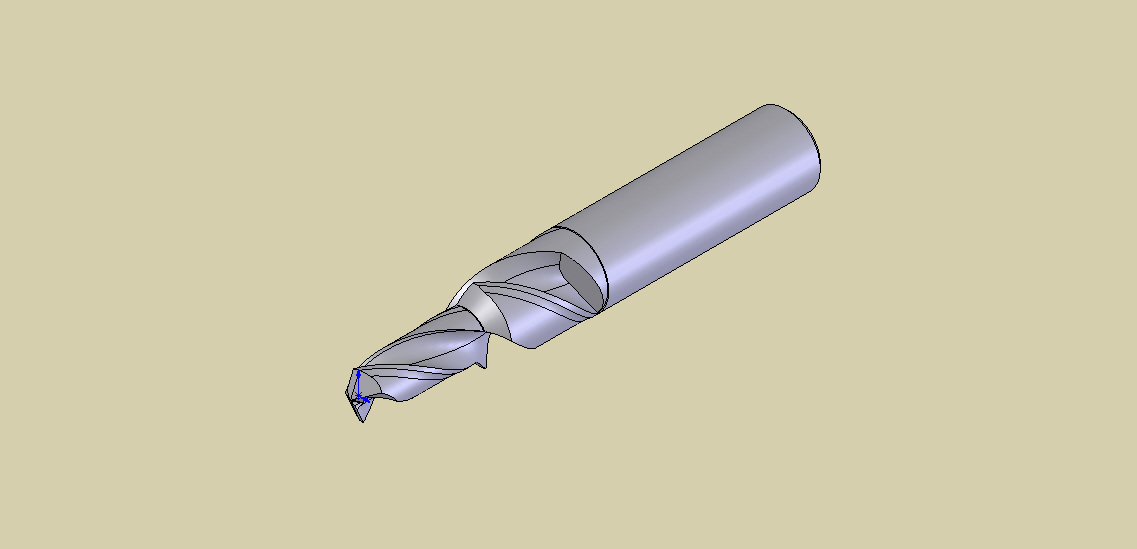

Standard Step Drill – Helical Flutes

The standard helical step drill can be made in HSS, COHSS, and carbide versions. HSS and COHSS drills are generally limited to non-coolant fed applications, while carbide drills are available in coolant fed and non-coolant fed versions. A helical flute design performs well in machining most material types and has the built-in advantage of mechanical chip evacuation due to helical flutes that promote extraction of chips from the drill point.

A wide variety of carbide coolant fed helix configurations are available including the popular 30° and 40° helix but 15° and 20° helix may be specified dependent on the application and the material being machined. For most step drill profiles the 40° helix is a likely choice. In high production applications, where tool life matters, tools are designed and helix angle selected to optimize cutting tool life.

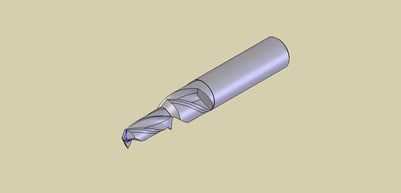

G-Drill – Straight Flutes

Straight flute G-drills are exceptional when machining cast iron, ductile iron, compacted graphitic iron (CGI), and aluminum. They also find use in brass and superalloys like Inconel, Inconel+, Rene, and other nickel base materials. Generally, G-drills are not recommended to machine steel and stainless steel alloys. G-drill geometries provide exceptional cutting edge strength due to the neutral cutting edge flute angle.

Straight flute G-drills are exceptional when machining cast iron, ductile iron, compacted graphitic iron (CGI), and aluminum. They also find use in brass and superalloys like Inconel, Inconel+, Rene, and other nickel base materials. Generally, G-drills are not recommended to machine steel and stainless steel alloys. G-drill geometries provide exceptional cutting edge strength due to the neutral cutting edge flute angle.

Tru-Edge incorporates a burnishing land for additional support when drilling. This allows for very round, straight holes with superior surface finish. For deep hole chip evacuation – tools greater than 5X diameter drilling depth - a coolant fed tool is needed to flush and remove chips at the point of cut. This is critical in vertical machining applications but also a best practice in horizontal applications.

G-drills are almost always made out of carbide material, as this substrate works best in the abrasive and very hard to cut materials.

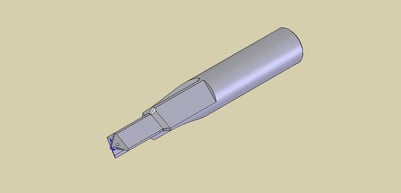

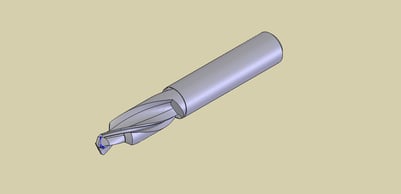

Subland Drill - Helical Flutes and Straight Flutes

Subland drills may be helical flute or straight flute although helical flute tools are the most prevalent. Subland drill geometry is often miss-understood. A subland tool is best described as drill with independent flutes of different diameters that are ground into a single, multi-function tool. From the tool design perspective the smaller drill diameter extends further down towards the shank beyond the point where the larger cutting step geometry is located. There are both advantages and disadvantages to a subland drill design.

Subland Drill Advantages

- Allows for more regrinds, especially on drills with a short step length.

- No undercuts in the pilot diameter on regrinds. This maintains the inherent strength of the tool and provides the maximum pilot margin length to assure stability in the cut throughout the life of the tool.

- Subland tools are higher in cost than traditional step tools due to design and manufacturing complexity. This is often offset by more regrinds per tool.

- Some designs allow for a dead sharp inside corner on a double angle step profile.

Subland Drill Disadvantages

- Adds complexity to drill design and manufacturing process.

- Special preform blanks may be required.

- Machining materials that require a high degree of back taper on the pilot diameter to avoid tool healing may negate the additional number of regrinds that a subland design offers.

- Pilot diameter may fall out of specification prior to reaching the desired number of regrinds.

- Tools with a large size variance in the pilot drill to the step diameter may weaken the tool.

Conclusions

Understanding the key elements of multi-function drilling tools is necessary to determine the best tool design for a given machining application. We design, quote, manufacture and deliver all types of special drills from old generation step drills to G-Drills to high-end subland drills with multi-flute geometry and complex CNC grinding requirements. Our tool engineering staff knows what to ask to ascertain which drill design offers our customers the best value. At Tru-Edge we are tool design specialists. We are “Tool Life Experts.”